Преимущества и специальные предложения

Double-post elevator Launch TLT-235SBA (220V) for servicing passenger cars and standard vans. Automatic control of stoppers (button from the remote control). Convenient location of the hydraulic station in the upper part of the elevator. Universal pick-up legs (length of the front - up to 1120 mm, rear - 1365 mm). Double protective ladder (cables and hydraulic hoses are protected not only by the upper ladder, but also by the lower metal box). Reinforced design of the elevator elements, pulleys of increased diameter. The thickness of the metal profile of the rack - 5 mm. Protection elements in the basic delivery set (hydraulic parachute valves, protection of moving mechanisms, protective frames on the pick-up legs). Lift height from 110 mm (two-section screw adjustment to increase the lift height). Maximum lifting height up to 1920 mm.

Technical specifications

| Elevation: | 1920 mm |

| Time to climb to maximum height: | ≤ 50 sec |

| Lowering time (adjustable): | 20 — 40 sec |

| Width of passage between carriages: | 2486 mm |

| Minimum height of pick-ups from the floor: | 110 mm |

| Noise level: | up to 75 dB |

| Motor parameters | 220 V / 50 Hz 2.2 kW |

| Cargo dimensions for shipping calculations: | TLT-235SB | TLT-240SB | TLT-235SBA | TLT-240SBA |

| Total weight: | 610 kg | 660 kg | 660 kg | 680 kg |

| Seat 1 (m): | 2.9 × 0.55 × 0.66 | 2.9 × 0.55 × 0.66 | 2.9 × 0.55 × 0.66 | 2.9 × 0.55 × 0.66 |

| Seat 2 (m): | 0.23 × 0.3 × 0.85 | 0.23 × 0.3 × 0.85 | 0.87 × 0.375 × 0.53 | 0.87 × 0.375 × 0.53 |

| Cumulative volume: | 1.11 m³ | 1.11 m³ | 1.22 m³ | 1.22 m³ |

| Features: | TLT-235SB | TLT-240SB | TLT-235SBA | TLT-240SBA |

| Load capacity according to European CE certification: | 3.5 t | 4 t | 3.5 t | 4 t |

| Stopper Control: | cable | cable | Electric actuator with remote control | Electric actuator with remote control |

| Hydropower Plant Location: | Bottom of the column | Bottom of the column | Top of the column | Upper part of the column |

| Compressor operating pressure: | 16 MPa | 18 MPa | 16 MPa | 18 MPa |

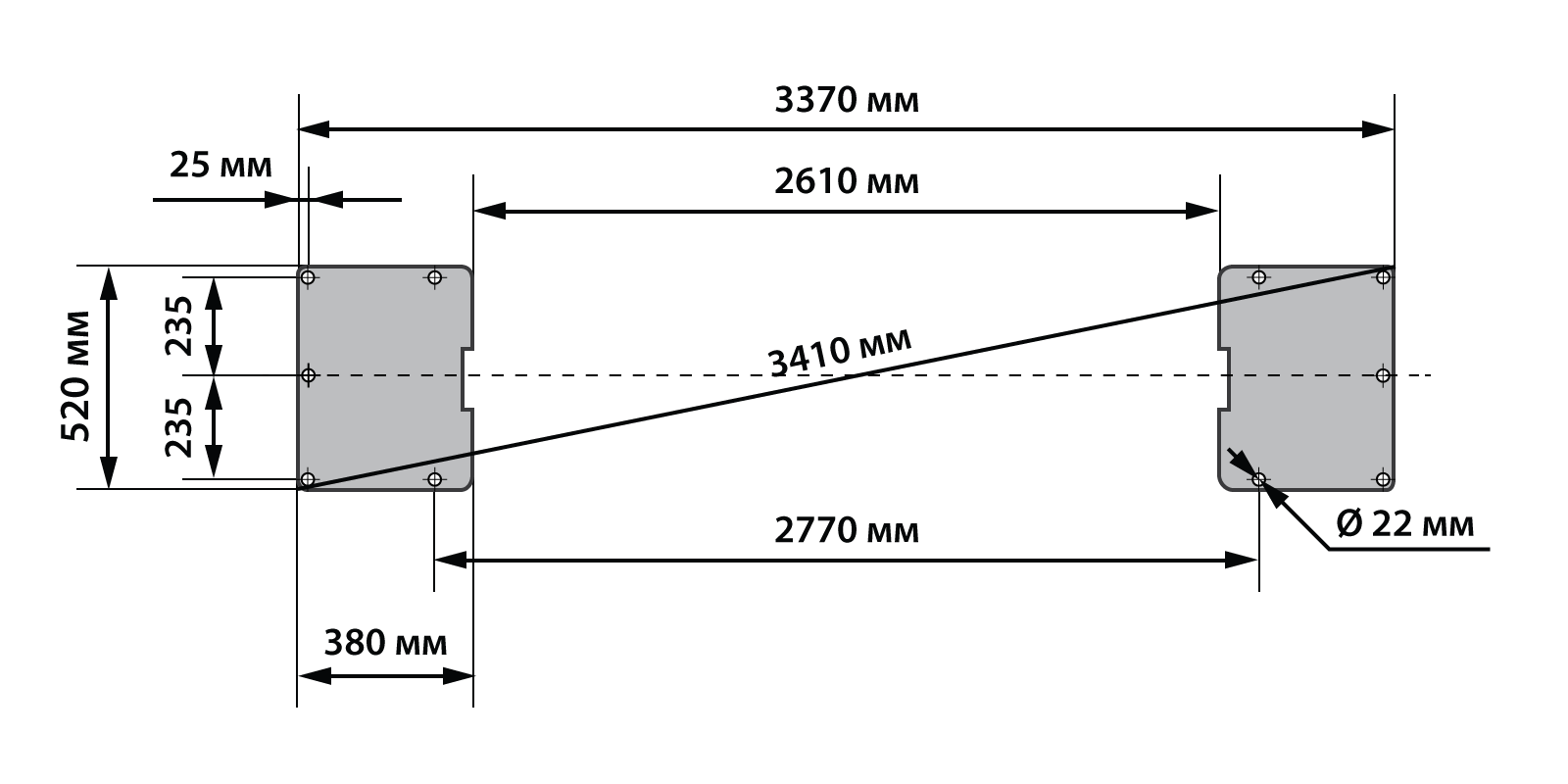

Dimensions

Installation dimensions

Equipment

|

Lift arm drive |

1 pc. |

|

Lift arm guide |

1 pc. |

|

Hydraulic power plant |

1 pc. |

|

Double gangway |

1 pc. |

|

Two-piece tines |

4 pc. |

|

Synchronization cable |

2 pc. |

|

Rack protection kit (rubber cover) |

2 pc. |

|

Fastener and fitting set |

1 pc. |

|

Wiring and hydraulic hoses and fittings |

1 pc. |

|

Electromagnetic stopper control system |

4 pc. (in SBA models) |

|

Protective cover of the stop solenoid |

4 pc. (in SBA models) |

|

Control panel |

1 pc. (in SBA models) |

|

Limit switch set |

2 pc. (in SBA models) |

The lower limit switch ensures safety by reminding you to check the space below the vehicle being lowered from 200mm from the floor (can be set to a different height or disconnected if required) (in SBA models).

The reinforced carriage profile distributes the load evenly and provides rigidity to the tine support system.

Comfortable and safe operation

Two-post elevators Launch in SBA modifications have a convenient control panel equipped with a 220V socket (protection class IP54). It has two modes of operation (manual and automatic) and emergency indication. Automated stop control system allows you to operate the elevator by simply pressing the Up/Down buttons, without the need to manually deactivate the stops: the system independently activates/deactivates the locking mechanisms and monitors the operation of the extreme positions of the elevator by the limit switches.

If it is necessary to lower the elevator - the mechanic simply presses the "Down" button, and the system itself raises the carriages, removes them from the stops and, holding the stops, lowers the car to a level of 20 cm from the floor, after which it

warns the mechanic with an audible signal about the proximity of putting the car and carriages on the floor. In case of emergency it is enough to release the button and the stoppers will come to the activated position.

A fully

manual mode of carriage and stoppers movement control is also available.

Convenient location of the hydraulic power plant, which has an increased resource compared to conventional Chinese elevators: in SBA modifications the pump and tank are located on the upper side of the column and do not interfere with the work with the

car.

The mechanism of manual emergency descent allows you to quickly and safely lower the car even in case of power failure.

Все комплектации

| Стоимость | Наличие | Тоннаж | Питание, В |

|

|

3.5 | ||

|

|

3.5 | 220 | |

|

|

3.5 | ||

|

|

3.5 | 220 | |

|

|

3.5 | ||

|

|

4 | ||

|

|

4 | ||

|

|

4 |